What We Can Offer You

Our Services

Over the past 30 years, Canon Safety has grown to become the leading provider of HSE Services, H2S Safety Services, Safety Training and Safety Program Development, OQ Services, and Technical Products Sales and Service for the oil and gas industry.

H2S Safety Services

Superior safety consulting

Canon Safety offers exceptional training for oil and gas workers who could be exposed to H2S during the course of their work activities. Keep your jobsite completely safe and efficient with our superior safety consulting and on-site safety personnel services.

Learn More

Training & Development

Safety Training & Development Services

Our training and consulting services are designed to ensure your personnel are extensively trained on the hazards of any jobsite, including hands-on training on performing tasks in accordance with industry standards.

Learn More

OQ Services

Veriforce, NCCER, OQSG

All of our Operator Qualification (OQ) services are built with your specific needs in mind. We have the knowledge, resources, and skills necessary to help you achieve your OQ goals.

Learn More

Safety Audits

In-depth safety audit experts

We work with owners and contractors in all aspects of the oil and gas industry to increase compliance and minimize injury through our in-depth safety audit services. Our certified experts are ready to perform a thorough evaluation of your operation.

Learn More

HSE Services

Health, safety, & environmental guidelines

Adhering to strict Health, Safety, and Environment guidelines is of the utmost importance to businesses in the oil and gas industry. Canon Safety is proud to offer superior HSE services to all of our clients.

Learn More

Equipment Rental

Cutting edge safety equipment

The safety equipment needs of the oil and gas industry changes with each passing year – that’s why we strive to meet the needs of our clients with a wide range of cutting edge safety equipment rental offerings.

Learn More

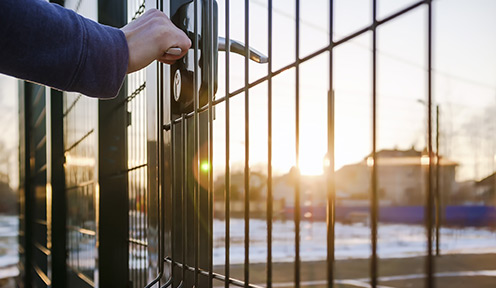

Gate Guard & Security

on-site security guard & patrol services

Maintaining active security personnel at your location offers a tremendous increase in safety and crime deterrence. That’s why Canon Safety provides comprehensive on-site security guard and patrol services for our clients.

Learn More

Gas Detection Sales & Service

Products & evaluation service offerings

Eliminate the inherent hazards of working with oil and gas with high-quality gas detection equipment sales, maintenance, and repair. Protect both people and property with Canon Safety’s exceptional products and evaluation service offerings.

Learn More

Compliance

Oil & gas industry compliance training & management services

Canon Safety provides experienced workplace safety consultants to offer OSHA and oil and gas industry compliance training and management services.

Learn More